판매용 중고 G&N IDS 34 #142089

URL이 복사되었습니다!

확대하려면 누르십시오

ID: 142089

빈티지: 2007

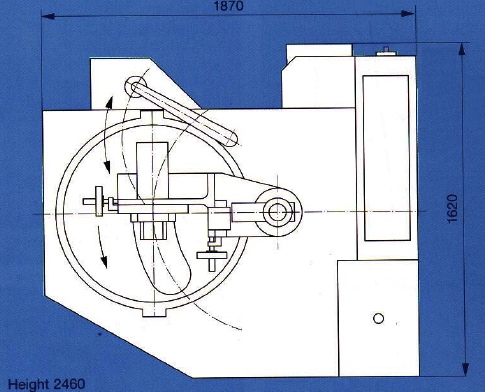

Inner diameter saw, 34"

Specifications:

Substrates capable: silicon, germanium, GGG, samariumcobalt, ferrite, glass, ceramic, semi-precious stones

Machine frame:

Vibration-free cast construction

Removable sheet metal covers on all sides

Swing type crystal holder: inner diameter saw blades up to 34" (860mm)

Frame rests on (6) shock and vibration absorbers

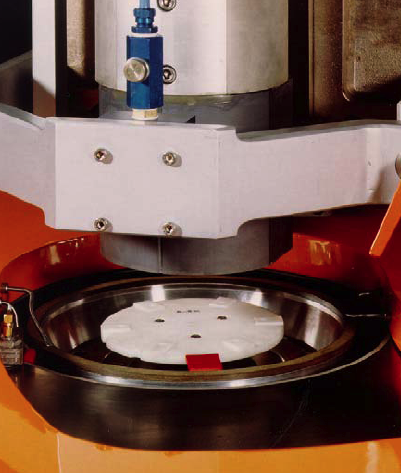

Blade mount:

Arranged horizontally

Axial and radial air bearings in optimum material combination

(2) Separate air connections for supply of air bearings

Air bearings sealed by labyrinth seals

Stationary inner cup: 260mm inner diamerter and (2) removable covers for control of the rotor disc

Massive rotor disc: heavy-duty special alluminum allow

Saw blade held by clamping ring

Spindle unit: horizontally adjustable, fitted to machine frame with (3) special screws

Supply pressure: 6 bar

Supply volume: maximum 30 m^3/hour

Axial runout of tensioning ring: less than 0.003 mm

Radial runout of tensioning ring: less than 0,015 mm

Radial runout of spindle pulley: less than 0.05 mm

If supply pressure drops below 4.5 bar, spindle drive is switched off via 2 air-lack differential switches, the monitors of axial and radial pressure

Top surface and inner diameter of supporting ring protected by welded stellite coat

Spindle drive:

AC motor: 3kW

Spring-pressure disk brake

Spindle drive: endless flat belt, grounding on both sides

Self-acting belt tensioning device

Power supply by electronic frequency converter

Spindle speed (infinitely variable): 500 to 1500 RPM

Spindle speed indication by 4-digit digital readout

Monitoring of the drive system by revolution control system

Machine automatically switched of if RPM is less than 900

Run-up time: less than 3 minutes

Run-down time: less than 2 minutes

Ingot infeed:

Arranged vertically to horizontal blade

Ingot clamping on the slide via holder, centering pin, quick clamping lever

Guide-ways of pre-loaded slide coated and grounded

Rolled ball screw pitch: 5mm

Top and bottom end position of the slide are limited by limit switches

Ingot dimensions:

Ingot dimensions: crystals up to 200mm ø and 570mm length

Orientation: ± 7° in (2) directions (scale graduation: 1 minute)

Thickness range: 0.6 to 6mm in 1µm increments

Index system repeatability: less than ±2µm

Infeed rates:

Up: 16 mm/sec

Down: 16mm/sec

Down: 2mm/sec

Cutting feed system:

Ingot feed mounted on massive, rigid, horizontal moving cast arm

Rests on large column and runs on (2) tapered polymer coated slide ways

Column clamped in a cast flange, screwed to machine frame

Cutting feed drive effected via ground ball screw, 2mm pitch, driven via disc gear motor, gimbal suspension of swing arm drive

Feed rate is infinitely variable, maximum 1800mm/min

Respective sawing positions can be preselected, monitored via potentiometers

Swing arm can be moved to extreme right hand position for saw blade or ingot change

Automatic wafer recovery system:

Wafer unloading within blade mount through 260mm dia bore of inner cup and air bearing spindle via a rigid linkage arrangement and a large surface vacuum chuck

Pick up chuck can be lowered 30mm, adjustable in end positions

Pick up chuck adjustable in (2) directions parallel to ingot to be cut

Additional height line feed

Vacuum and the back air for sawn wafer supplied thorugh linkage

Wafer transfer: blade bore

Swiveling handling arm with vacuum head takes sawn wafer from pick up chuck, lifts off and swivels through 900 to the rear

Wafer discharged in rear end position

Automatic switch off if wafer breakage or incorrect pick up

Possible control functions:

Set up:

All functions are operated individually, feed and infeed are interlocked

Single cut:

One feed motion without return

Automatic:

Fully automatic operation with automatic unloading

Pack slicing:

Adjustable for 1 to 999 cuts via three-decade selector switch

Signal bulbs:

Indication of faults: lack of air, vacuum, filter faults are indicated by signal lamps

Measuring and control unit Micro-Epsilon:

For monitoring and controlling saw blade with respect to saw quality and connected characteristics of saw blade

Supplies operator with information about possible unnecessary dressing procedures

Contactless gauging unit measures saw blade deviation during cutting cycle

Technical data:

Crystal range (dia x l): maximum 200 x 570mm

Packet cut of (2) crystals up to 125mm ø each

Sawblade diameter: 860 x 304mm

Rotational speed of spindle (infinitely variable): 500 to 1500 RPM

Spindle and drive:

Spindle: aerostatic bearings

Motor: 3kW, mechanical brake

Sawing feed:

Feed rate (infinitely variable): 0 to 150 mm/min maximum

Return speed: 1800 mm/min

Index system: 0.6 to 6mm

Indexing accuracy: 5 ± 2µm

Indexing speed: maximum 1500 mm/min

Orientation:

Adjustable: + 7° in two levels

Coolant:

Flow rate adjustable: up to 12 L/h

Indication: flow meter

Hydraulic system:

Pump: 0.55kW

Tank volume: 25 L

Pressure: 35 bar

Services:

Connected load: 7kW

Electrical supply: 220/380V, 50Hz

Compressed air: 6 bar

Features:

Automation:

Unloading device and vertical arrangement of crystal: automatic withdrawal of individual wafers without stopping machine

Simultaneous operation of other machines is possible

Predetermined number of wafers can be semiautomatically packet cut

Ergonomics:

Horizontal arrangement of sawhead allows for access and fitting of sawblade with (2) clamping collars

Precision:

Entire sawhead runs in radial and thrust aerostatic bearings

Adjustable on all levels

Electronic control and closed loop measuring system

Smallest infeed increment: approximately 0.6mm

Repeatability: < + 2µm

Rigidity:

Rigid construction and dynamically balanced rotating components

Demonstration machine

CE marked

2007 vintage.

G&N IDS 34는 독일 회사 Gerd & Netzgert가 만든 최첨단 스크리빙 및 다이빙 장비입니다. 이 "스크리빙 '과" 다이빙' "시스템 '은 강력 하게 설계 되어 많은 혁신적 인 특징 을 제공 한다. 이 장치는 서보 제어 공압 클램핑 시스템을 사용하여 모터 구동 (motor-driven) 절단 블레이드의 이동에 따라 가장 높은 정밀도를 보장합니다. 또한 서보 제어 장치 포지셔닝과 블레이드 어셈블리 (Blade Assembly) 를 조합하여 절삭 작업을 신속하게 완료합니다. 잘라낼 수 있는 "커팅 헤드 '는 완전 히 완성 된 제품 을 달성 하는 데 도움 이 된다. 강력한 기반 외에도 IDS 34 는 다양한 성능 기능을 제공합니다. 이 시스템은 단순하고 사용자 친화적인 제어 장치 (Control Unit) 를 갖추고 있어 코드와 제품 데이터를 빠르고 직접 입력할 수 있습니다. 사용자 인터페이스는 처리 주기를 처음부터 끝까지 관리하는 데 도움이 됩니다. 또한 프로세스 진행 상황을 실시간으로 모니터링하여 최고의 품질 (Quality of product) 을 보장합니다. G&N IDS 34 는 운영자 친화적 처리 (operator-friendly handling) 를 위한 준비 툴이 포함되어 있으므로 한 제품에서 다른 제품으로 손쉽게 전환할 수 있습니다. 또한, 이 도구는 인체 공학적으로 설계된 머신 베이스로, 모든 작업 환경에 적합합니다. 이 스크리빙 및 다이빙 자산은 머시닝의 유연성도 허용합니다. 두께는 최대 0.8mm, 길이는 최대 35mm 인 재료를 처리 할 수 있습니다. 절단 면적은 최대 50 x 50mm, 절삭 깊이는 최대 12mm로 설정할 수 있습니다. 톱 (saw) 테이블의 부분 이동성은 가장 복잡한 컨투어조차도 탐색하는 데 도움이됩니다. IDS 34 에는 블레이드와 가공소재를 정확하게 정렬할 수 있는 레이저 포지셔닝 (laser positioning) 모델이 장착되어 있어 속도와 정확도가 향상됩니다. 또한, 가장 복잡한 부분의 정확한 절단을 제공합니다. G&N IDS 34 장비는 매우 짧은 주기 (cycle time) 로 정확하고 정확한 절단을 제공하는 탁월한 솔루션입니다. 이 시스템은 혁신적인 기능과 사용하기 쉬운 운영자 인터페이스 (operator interface) 를 통해 안정적이고, 정확하며, 고품질의 제품을 제공할 수 있습니다.

아직 리뷰가 없습니다